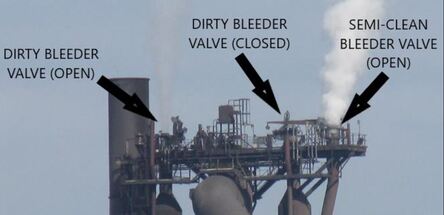

Above photo... gas flare from the co-gen illuminates the stack and opened bleeder valve(s) of #7BF

BLEEDER VALVES

Bleeder valves are located in several locations and can be opened

Bleeder valve emissions are a breach of air quality regulations if the opacity exceeds 20% and lasts more than 6 minutes.

Bleeder valves are located in several locations and can be opened

- manually during maintenance procedures or shut-downs

- automatically when internal pressures become too great or a during a larger full system failure

- accidently by human error

- accidently when there is an equipment failure (eg. a faulty sensor or sticky valve)

Bleeder valve emissions are a breach of air quality regulations if the opacity exceeds 20% and lasts more than 6 minutes.

STACK FLARES

The coke ovens run continuously and produce coke oven gas which is burned in several locations throughout the plant ( coke-oven batteries, reheat furnaces, the boiler house and the cogen plant ) and exhausted upwards through several chimneys ("stacks").

This gas cannot be stored. If there is a surplus, the gas is intentionally burned at the mouth of Flaring Stacks.

The coke ovens run continuously and produce coke oven gas which is burned in several locations throughout the plant ( coke-oven batteries, reheat furnaces, the boiler house and the cogen plant ) and exhausted upwards through several chimneys ("stacks").

This gas cannot be stored. If there is a surplus, the gas is intentionally burned at the mouth of Flaring Stacks.

STANDPIPE FLARES

Before pushing an oven, a damper between the oven pipe and the collecting main is closed or “dampened off” to prevent oxygen from entering the gas collector main. That is a safety requirement to ensure there is not an explosive gas mixture inside the gas main. The next step is to open the standpipe lid and a charge hole lid in order to ignite the gas and destroy some of the contaminants present in the gas. Once lit, there will be visible flames at the top of the standpipe until the oven is pushed. This flame should only be visible for a short period of time.

Multiple flares over any extended period of time are NOT normal and represent an "upset" which should be reported.

Before pushing an oven, a damper between the oven pipe and the collecting main is closed or “dampened off” to prevent oxygen from entering the gas collector main. That is a safety requirement to ensure there is not an explosive gas mixture inside the gas main. The next step is to open the standpipe lid and a charge hole lid in order to ignite the gas and destroy some of the contaminants present in the gas. Once lit, there will be visible flames at the top of the standpipe until the oven is pushed. This flame should only be visible for a short period of time.

Multiple flares over any extended period of time are NOT normal and represent an "upset" which should be reported.

|

EMAIL: [email protected]

|

CLEAN NORTH www.cleannorth.org |

Follow STACKWATCHSSM ON FACEBOOK (2) Stackwatchssm | Facebook Visit: www.ecosenshi.com for more background information |

Proudly powered by Weebly