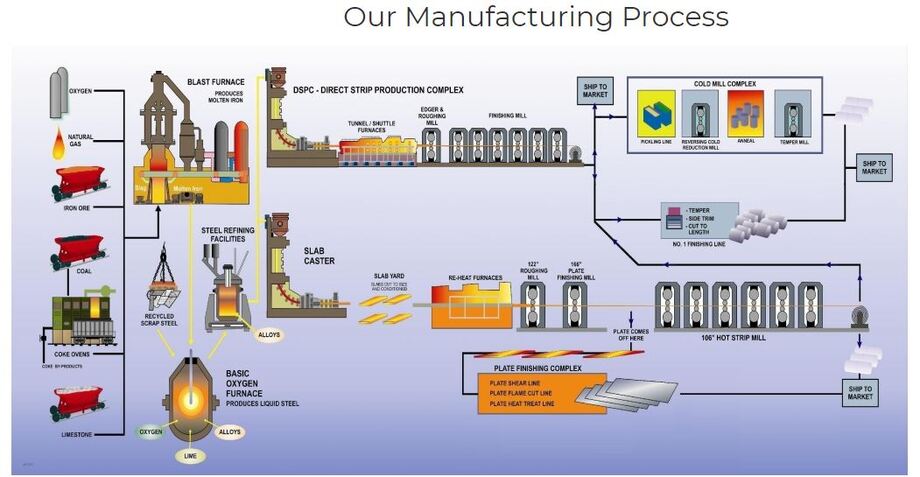

ALGOMA STEEL INC is an "integrated steel" company.

An integrated steel mill has all the functions for primary steel production:

Because of the energy cost and structural stress associated with heating and cooling a blast furnace, typically these primary steel making vessels will operate on a continuous production campaign of several years duration. Even during periods of low steel demand, it may not be feasible to let the blast furnace grow cold, though some adjustment of the production rate is possible.

Integrated mills are large facilities that are typically only economical to build in 2,000,000-ton per year annual capacity and up.

In the BOSP alloys are added to alter the chemical and physical properties of the final product to meet the specifications of the final customer. At ASI the finished liquid steel is rolled into plates or strips/coils.

A major environmental hazard associated with integrated steel mills is the pollution produced in the manufacture of coke, which is an essential intermediate product in the reduction of iron ore in a blast furnace.

Integrated mills may also adopt some of the processes used in mini-mills, such as arc furnaces and direct casting, to reduce production costs.

An integrated steel mill has all the functions for primary steel production:

- Iron making (conversion of iron ore into liquid iron/"pig" iron)

- Steel making (conversion of pig iron to liquid steel),

- Casting (solidification of the liquid steel),

- Rough rolling (reducing size of blocks)

- Product rolling (finished shapes).

Because of the energy cost and structural stress associated with heating and cooling a blast furnace, typically these primary steel making vessels will operate on a continuous production campaign of several years duration. Even during periods of low steel demand, it may not be feasible to let the blast furnace grow cold, though some adjustment of the production rate is possible.

Integrated mills are large facilities that are typically only economical to build in 2,000,000-ton per year annual capacity and up.

In the BOSP alloys are added to alter the chemical and physical properties of the final product to meet the specifications of the final customer. At ASI the finished liquid steel is rolled into plates or strips/coils.

A major environmental hazard associated with integrated steel mills is the pollution produced in the manufacture of coke, which is an essential intermediate product in the reduction of iron ore in a blast furnace.

Integrated mills may also adopt some of the processes used in mini-mills, such as arc furnaces and direct casting, to reduce production costs.

|

EMAIL: [email protected]

|

CLEAN NORTH www.cleannorth.org |

Follow STACKWATCHSSM ON FACEBOOK (2) Stackwatchssm | Facebook Visit: www.ecosenshi.com for more background information |

Proudly powered by Weebly